Variable Geometry Turbochargers

Go ahead, give me some mumbo-jumbo talk. Okay, save the embarrassment and admit that you don’t know.

I’ve often told the story of being an embarrassed speaker in front of a crowd as I tried to explain why a diesel engine is more efficient than a gasoline engine for a given size of engine displacement. Can you explain the answer to this very basic question?

“The diesel fuel has a higher BTU content.” Really?

“It can be turbocharged.” Really?

“The diesels have injectors and fuel pumps.” Really?

“The diesel has a higher compression ratio.” Really?

Really, if you want the long answer it is found at the start of each Turbo Diesel Buyer’s Guide* books that we’ve published. The article is titled “Why a Diesel?” (The simple answer is that the gasoline engine mixes 14 parts of air to 1 part of fuel and ignites the mixture with a spark plug. The design of a diesel (big robust block and cylinder heads, fewer revolutions per minute, higher compression ratio) makes use of the fact that compressed air is hot. Using a fuel pump and injectors, we can vary the amount of fuel that is injected into the diesel’s cylinder of hot compressed air in order to make it ignite. In an idle situation it’s 85 parts of air to one part of fuel. At full load it’s 20 parts of air to one part of fuel. With a diesel you can vary the air to fuel ratio based on the load factor. As mentioned, with the gasoline engine it is always 14 parts of air to one part of fuel and the ignition is initiated by a spark plug. Got it?

Back to the story: What is a Variable Geometry Turbocharger (VGT)? Better yet, what advantage does the Holset variable geometry turbocharger design give Ram/Cummins over the competitive Ford and Chevy guys? (How about the Ram 1500 EcoDiesel, doesn’t it have a variable geometry turbocharger?).

Like many topics, this one has been covered before in the Turbo Diesel Register. However, the audience is forever changing and often we old-timers need an update to bring us into sync with the different VGT designs that are being offered in the marketplace.

What? There are different definitions of “variable” in the variable geometry turbocharger? Yes, VGT is not a one-size-fits-all product.

Let me see if I can keep this easy to understand and then I’ll add some technical stuff for the gearheads in the audience.

The basics: Holset turbochargers are a division of Cummins and the Holset folks have a patent on the sliding vane design of “variable” geometry.

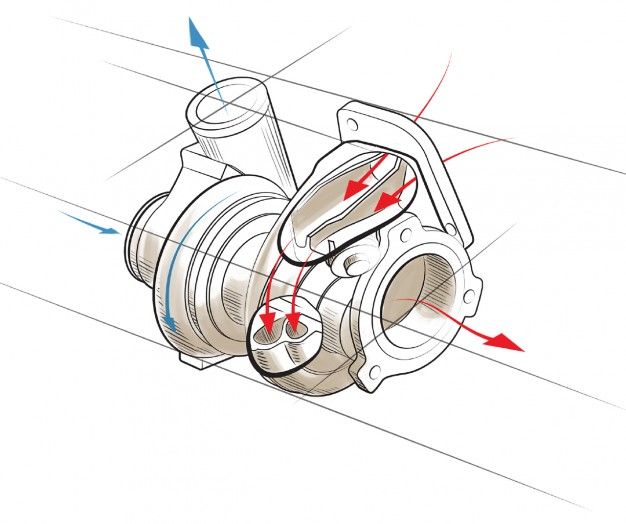

VIEWS ON HOW THE SLIDING VANE OPERATES

In this diagram, The sliding vane is CLOSED in the above diagram.

Exhaust gas flow (small red arrow, top left)is restricted and thus, the turbocharger is acting like an exhaust brake. Allow the vane to move to the right and the exhaust gas flow is :full on" causing the turbine (exhaust) blades of the turbocharger to spin faster and create more boost.

Sliding Vane is CLOSED

Holset HE351 from a 6.7L

With the sliding vane fully extended, the turbo blades are closed to exhaust flow. This creates exhaust gas back pressure (the exhaust cannot escape) and the turbo acts like an exhaust brake.

Sliding Vane is OPEN

Holset HE351 from a 6.7L

With the sliding vane totally fully retracted, the turbo blades are open to exhaust flow. Exhaust flows freely and the pressure

on the turbine blades builds intake air boost/pressure.

Car and Driver on Turbochargers

Interestingly, in June 2016, Car and Driver magazine had a pictorial showing various turbocharger designs that are used in automotive applications. As you might imagine, the Holset sliding vane/variable geometry turbocharger was not included.

However, the C&D article gave the audience a picture example of the rotating vane/variable geometry turbo that we’ve already pictured. For the sake of education, I’m going to post their pictures of the twin scroll, twin turbos and sequential turbos so that you’ll know the terminology that is used in the business. ) By the way, the term “twins” is all-too-often used incorrectly by folks who actually have sequential turbos, so beware.

Twin Scroll Turbocharger

The exhaust manifold and turbine housing split the exhaust into two segregated streams. This optimizes the timing of the exhaust pulses delivered to the turbine wheel, improving response when the throttle position changes abruptly.

(Car and Driver Illustration)

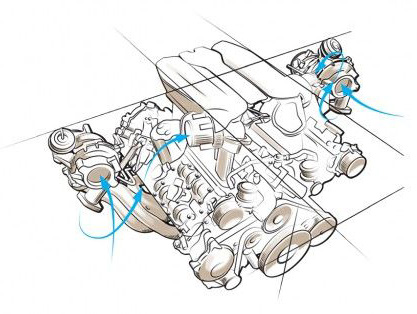

Twin Turbochargers

Two equal-sized blowers are each fed by half an engine’s cylinders. Using two turbos rather than one leads to smaller turbine and compressor wheels that spool quicker due to their lower inertia.

(Car and Driver Illustration)

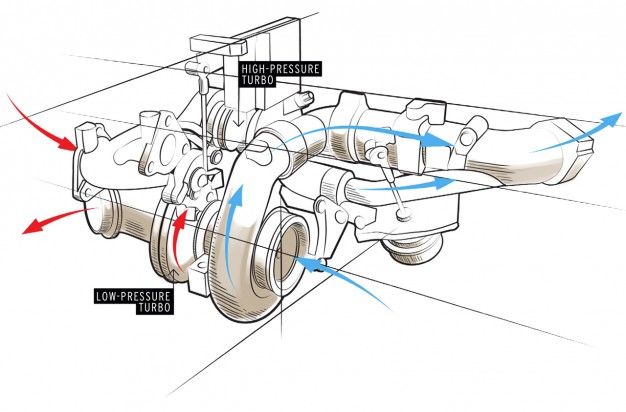

Sequential Turbochargers

Here, a smaller turbo spools quickly for low-end responsiveness while a larger unit boosts top-end power with higher volumes of exhaust. Sequential setups have fallen out of favor because they require complex controls and bulky packaging, and recent advances have reduced spool-up lag in single and twin-turbo setups.

(Car and Driver Illustration)

Up on a pedestal (and rightfully so), this Holset HE351 VGT (above) is the key to managing intake air pressure for economy, power and emissions.

NOW, WHICH DESIGN IS BETTER? HOLSET'S SLIDING VANE?

Which design is better? What are the features and benefits of these various turbocharger designs?

The balance of the article cannot be answered with a simple Wikipedia search. Also, in my research of YouTube and manufacturer websites, there was too much mumbo-jumbo. So, let’s go right to the source: Cummins/Holset’s John Clark for some guidance and understanding. I interviewed John and asked him to take off his “corporate colors” and help the audience. The following are excerpts from the conversation:

THE BOTTOM LINE

John was quick to get right to the bottom line. John said, “Look closely at Holset’s patented sliding vane design and picture when the vane is in the closed position, it blocks the flow of exhaust! If the exhaust is blocked, the engine is working against itself: stalled out, if you will. With the driveline directly connected (manual transmission or lock-up torque converter) the engine slows the truck. All the other VGT guys’ turbochargers do not block the exhaust flow. Big advantage Cummins/Holset.”

John continued: “The rotating vane design used by everyone else in the business does not have this feature.”

End of interview.

Seriously, John went on to tell me that Holset first implemented a sliding vane design turbocharger in 1998 for a medium duty diesel engine used in Europe. The next application was in 2002 on Cummins’ 15-liter ISX big-rig engine. It was first used on the B-Series engine in the 2007.5 Ram truck with the 6.7-liter engine, as it gave Ram/Cummins an advantage over the competitive diesel pickups in the North American marketplace (read: Ford and GM). Today, 10 years later, Ram/Cummins still enjoy that competitive advantage. Cummins uses the Holset sliding vane turbocharger in engines from 2.8-liters up to 15-liters in displacement.

CONCLUSION

Short and sweet: Ram/Cummins owners have a distinct advantage with the ’07.5-current 6.7-liter engine’s sliding vane turbocharger and its exhaust brake feature.

Go ahead, walk around with the smugness of superiority.

Robert Patton

TDR Editor

This article originally appeared in the Turbo Diesel Register, Issue 110, Page 34.

* The Turbo Diesel Buyer's Guides are available to TDR members and are published for most model year Dodge and Ram Cummins Turbo Diesel pickup trucks. Check out the TDR at: www.turbodieselregister.com. Annual membership is $35 per year, you can subscribe here: www.tdr-online.com